EXAIR static eliminators

We offer a comprehensive range of products and solutions to remove static electricity, dust and other contaminants in various industrial processes. Static electricity can also cause materials to stick together or to machinery, creating problems in production. High levels of static electricity can also be a safety hazard for employees or cause damage to machinery.

Static eliminators neutralise static electricity by emitting positive and negative ions. When a charged surface attracts these ions, it becomes neutralised. EXAIR static elimination solutions include both compressed air assisted and non-air static eliminators, each tailored to meet specific needs.

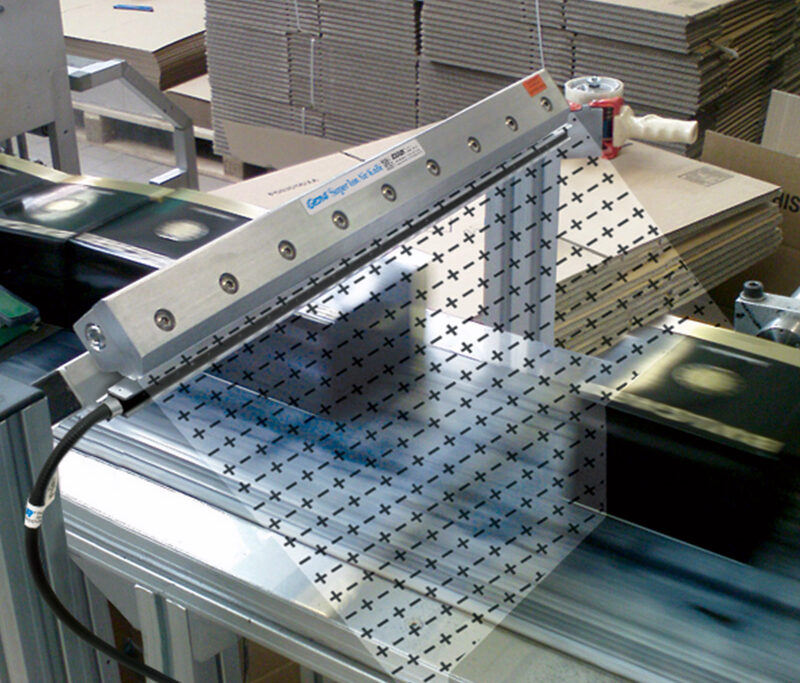

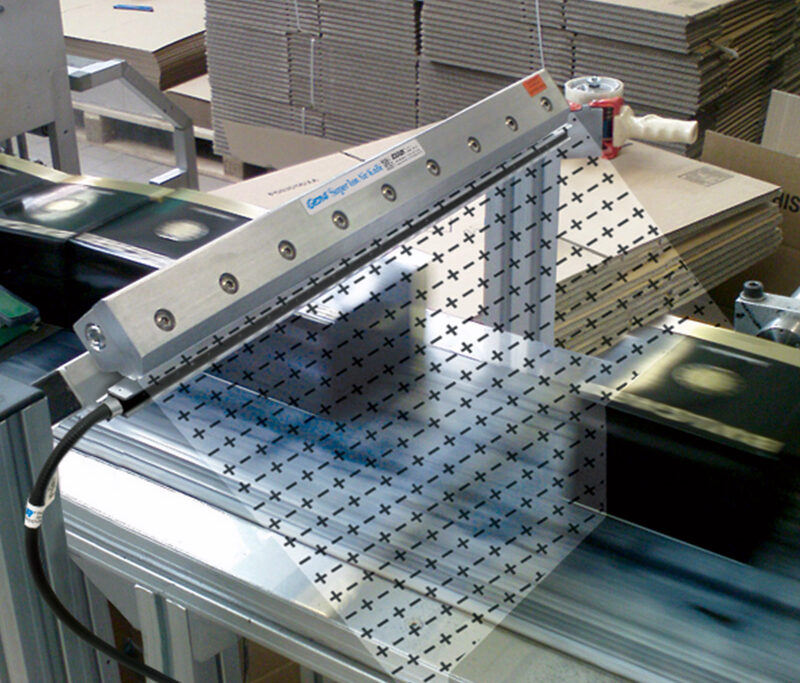

Gen4 Super Ion Air Knife

Extra strong laminar airflow to remove static electricity.

Gen4 Standard Ion Air Knife

Effective air knife to remove static electricity from plastic, paper sheets and other surfaces.

Gen4 Super Ion Air Wipe

360° ionised airflow that effectively removes static electricity from pipes, cables, etc.

Gen4 Ion Air Cannon

Removes static electricity up to a distance of 4.6 metres. Compact and efficient.

Gen4 Ion Air Gun

Handheld ionisating air gun to easily remove static electricity.

Gen4 Ion Air Jet

Effectively removes static electricity at various points in production. Compact and powerful.

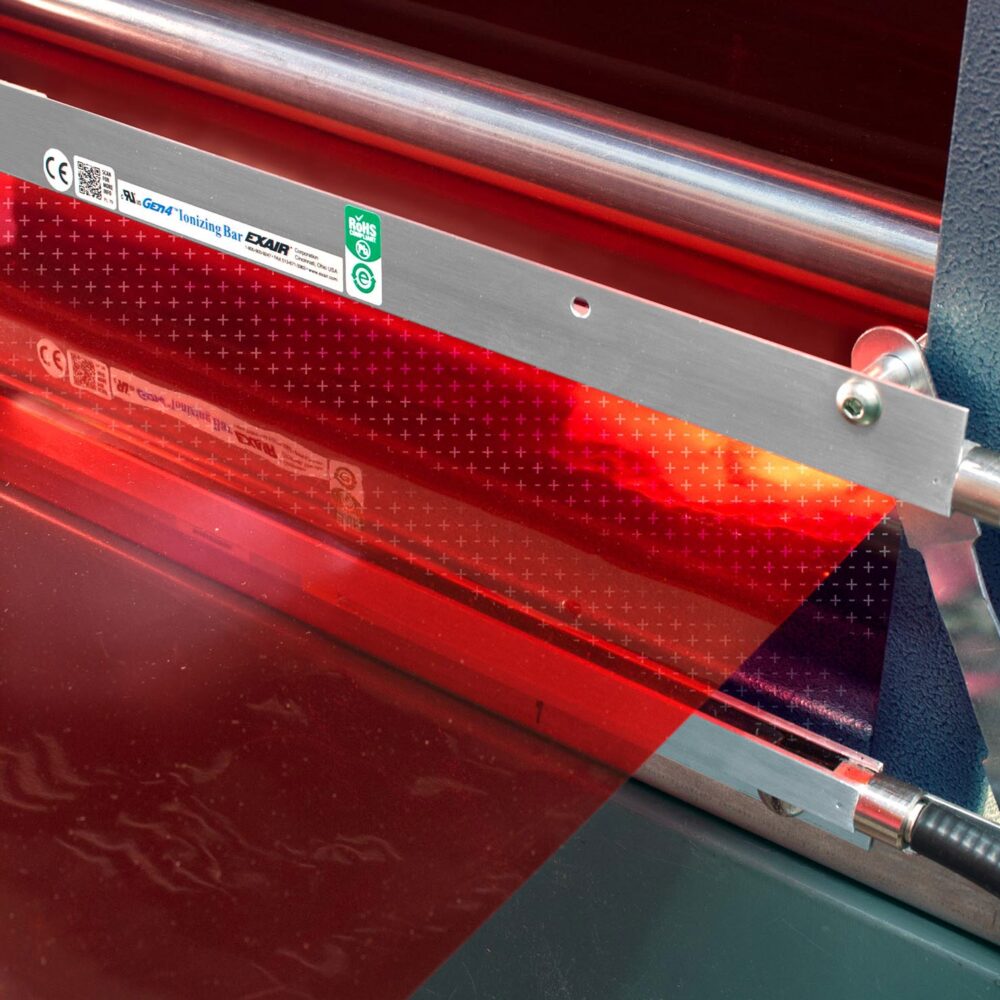

Gen4 Ionising Bars

Ionising bars for neutralising static electricity.

Gen4 Ionising Point

Removal of static electricity at a specific point in production.

Gen4 Power Supply

Power supply with selectable input voltage 115V or 230V for EXAIR Gen4.

Intellistat Ion Air Gun

Patented, ergonomic ionisaint air gun to quickly remove static electricity.

Intellistat Ion Air Nozzle

Mountable ion air nozzle for removal of static electricity at assembly stations and workbenches.

Varistat Benchtop Ioniser

Benchtop-mounted unit to quickly neutralise static electricity on workbenches and assembly stations.

Digital Static Meter

Handheld and easy-to-use static meter that quickly identifies static electricity.

AC Sensor

Contactless voltage detector. Red-light indicator and audible signal.

Neutralising static electricity with or without compressed air? What is the difference?

To remove static electricity in production, you can choose between anti-static solutions that operate with or without compressed air.

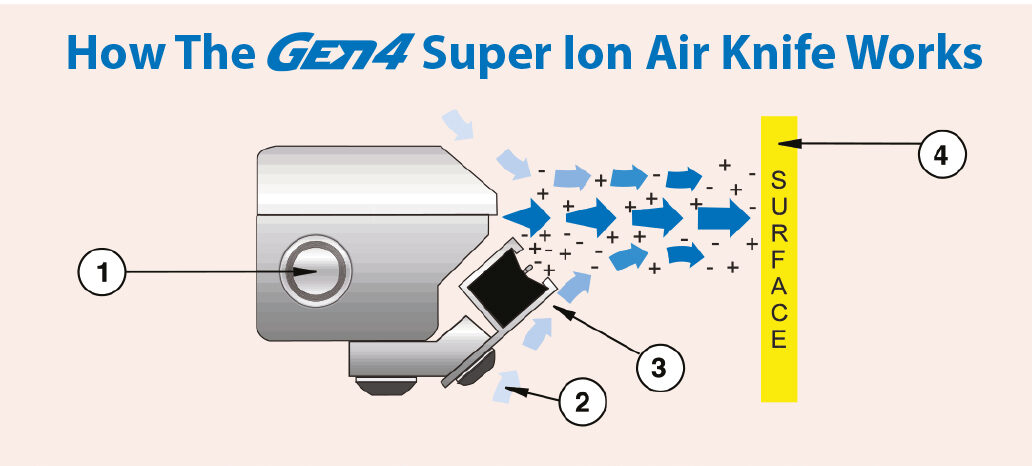

Gen4 Super Ion Air Knife - deionisation with compressed air

The air knife combines ionisation with airflow to quickly remove static charges and contaminants over large surfaces, moving parts and hard-to-reach areas.

Compressed air flows through an inlet (1) into the plenum chamber of the Gen4 Super Ion Air Knife. The flow is directed into a precise, slit-shaped opening. As the primary airflow passes out, it forms a smooth air blade along its entire length, which instantly entrains the surrounding air (2). An electric Gen4 ionising bar (3) fills the air curtain with positive and negative charges. The airflow of these static elimination ions to the product surface (4), where it instantly neutralises static electricity and blows away dust and other particles.

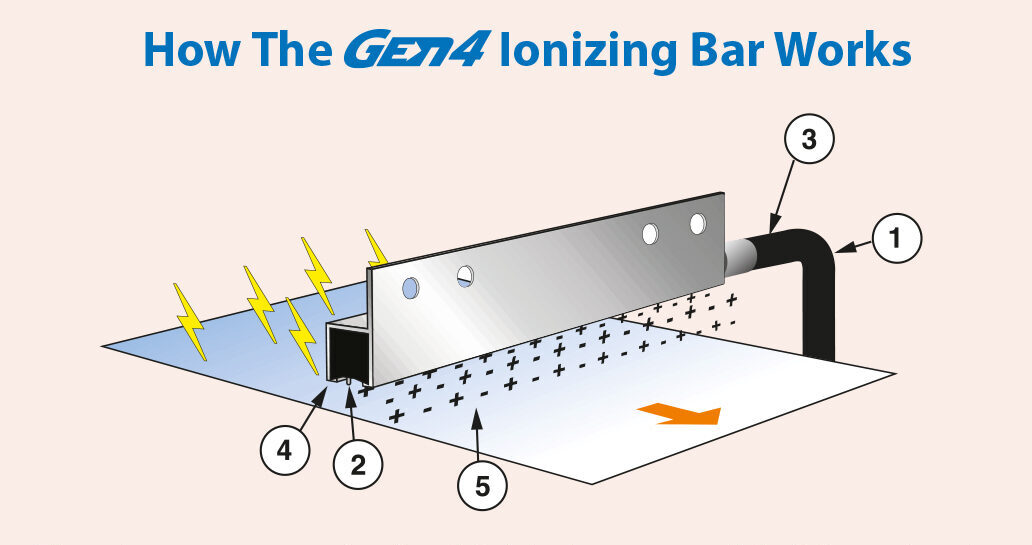

Gen4 Ionising Bar - deionisation without compressed air

Ideal for use on delicate or lightweight materials, which may be adversely affected by an air flow. Compact and efficient solution for close-range applications.

The electromagnetically shielded power cable (1) conducts 5 kVrms from the power supply to each inductively coupled stainless steel emitter tip (2) on the Gen4 Ionising Bar. An integrated ground wire (3) in the power cable creates a discharge path from the emitter tips to the rod body (4). The discharge at each emitter charges the gas molecules in the surrounding air, resulting in a flow of positively and negatively charged ions (5). If the material surface has a negative charge, it attracts the positive ions from the Gen4 Ionizing Bar and becomes balanced or neutralised. If the material surface has a positive charge, it attracts the negative ions from the Gen4 Ionizing Bar and becomes balanced or neutralised.

How to choose the right type of product to remove static electricity in production?

Here is a brief summary of what you might want to consider to choose the most suitable product or solution to remove static electricity in your production process.

Material

What is the type of material to be treated? If it is a delicate or lightweight material that might be affected by an air flow, it is more appropriate to use a Gen4 Ionising Bar which removes static charges without the use of compressed air.

Surface area

To remove static electricity from large surfaces or areas, it is more effective to use a product that combines ionisation with an air flow. There are a variety of products to choose from - including different types of ionisation air knives and ionisation guns.

Movement

Is the material in motion? Then it is best to use anti-static products that use compressed air and are very effective in removing static electricity and other contaminants over large areas, but also over long distances.

Amount of static electricity

If there is a lot of static electricity to be neutralised, deionisation with compressed air works best.

Installation

Is there plenty of space around the material to be treated? If not, it may be beneficial to use Gen4 Ionising Bar without compressed air, as it has a more compact design.

Contact one of our experts

Call, email or book a web meeting with one of our experts specialising in EXAIR Compressed Air Products. We will advise you on the most suitable product or solution in order to achieve an efficient and safe industrial process.

A short web meeting is usually a time-efficiently way to gather information to advise on the right product or solution. During a web meeting we can quickly and easily obtain information on the various factors that may influence the choice of equipment and solution to achieve the most effective result. Sometimes a site visit may also be a good idea, depending on your preference. Of course, you can also just call or email!

When suggesting a suitable product or solution we take into account - function, lifespan, quality, choice of material, and operating and maintenance costs. Our goal is to deliver a sustainable solution that creates added value for you as a customer.

Documents for download

Book a web meeting

Book a short web meeting with one of our experts to go through any questions you have about our products, applications or solutions.

Quick response time & technical support

We are available weekdays 08-16.30!

Knowledge base

We would like to share our knowledge and experience with you. In the Knowledge Bank you will find a variety of questions, explanations and process descriptions in our different product areas.