Spray nozzles and spray systems

We are specialists in spray nozzles and industrial spray processes offering a complete range of spray nozzles and spray solutions.

Spray nozzles are divided into different categories depending on how the nozzle spray is shaped. The nozzle spray can for example be shaped like a cone, a straight line, or a fine mist. The size of the droplets in the nozzle's spray is also important to consider to choose the right spray nozzle and optimise the spray process. Below you will find our complete range of spray nozzles sorted under the categories – full cone nozzles, hollow cone nozzles, flat fan nozzles, misting nozzles, air atomising nozzles, automatic nozzles, and spray lances & spray systems.

To optimise the spray process, it is important to understand how a spray is affected in different environments and in different conditions. By combining our extensive internal resources with our customers' knowledge, we quickly and efficiently solve both simple and complex spray applications. Our team provides guidance and technical expertise in selecting products.

Full cone nozzles

The full cone nozzle is the most common type of spray nozzle in industry and distribute liquid over a circular area.

Hollow cone nozzles

The hollow cone nozzle is used when you want the volume flow to be concentrated on the outer part of the spray cone.

Flat fan nozzles

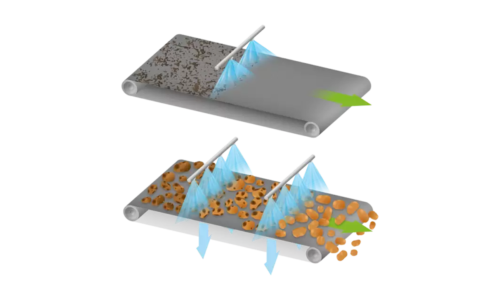

The flat fan nozzle is very efficient for various rinsing and washing processes. The droplets are relatively large compared to other nozzles and the spray has high impact.

Misting nozzles

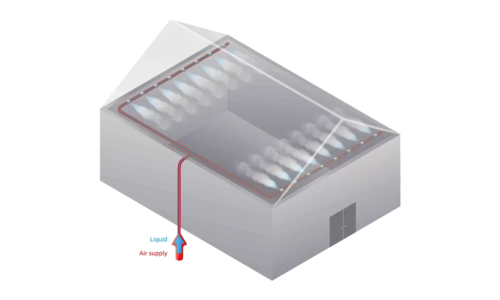

Mist nozzles create a spray consisting of very small droplets even at low pressures. Used for humidification, cooling, surface treatment, etc.

Air atomising nozzles

Air atomising nozzles create a very fine spray of small droplets. Used for cooling, humidification, lubrication, surface treatment, etc.

Automatic nozzles

Spray nozzles with intermittent spray are used when you need high dosing precision and to avoid costly waste in the process.

Spray lances & spray systems

Spray nozzles for injecting liquid and gas into various process flows, as well as other customised solutions for specific requests and needs.

Accessories

Various accessories for easier installation and a more efficient spray process.

Complete range of spray nozzles

Our full range of spray nozzles and spray systems listed in alphabetical order.

Support & Service

We offer advanced engineering, spray testing, CFD modelling, customised labelling of nozzles, etc.

Our main supplier of spray nozzles & spray systems

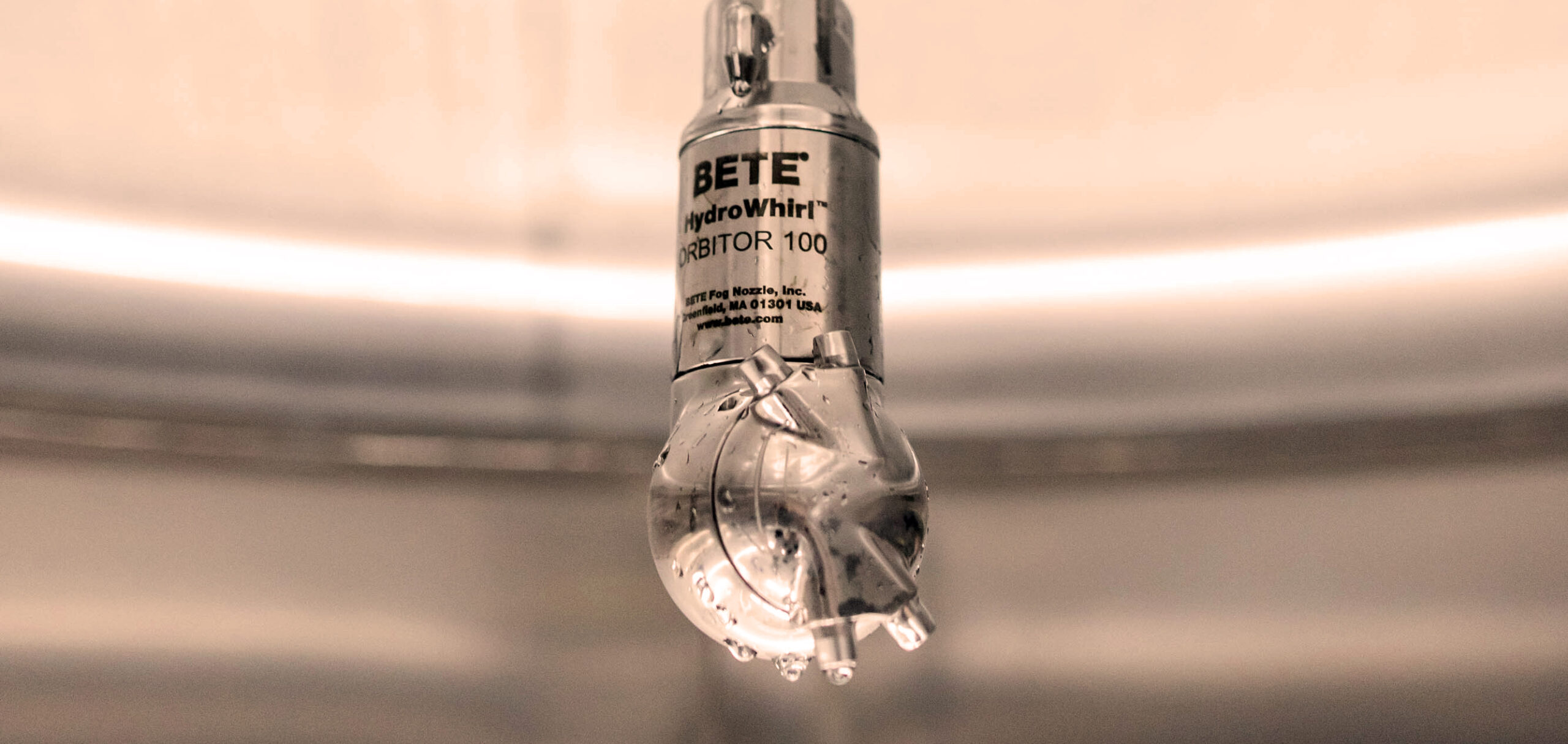

BETE is a leading manufacturer of spray nozzles and spray systems with more than 70 years of experience in spray processes and a product range including over 20,000 components.

BETE's spray nozzles and spray systems are used worldwide to optimise processes in many different industries, including the energy sector, chemical and petrochemical industry, food industry and offshore.

BETE offers test facilities, CFD modelling, and advanced technical support. To ensure high quality and reliable deliveries, BETE's manufacturing of spray nozzles and spray systems is largely based 'in-house' with its own foundry, CNC machining, assembly and quality control.

Spray nozzles and everything else for your spray system

Various types of industrial spray processes require different technical solutions. Here you will find everything related to spray nozzles, spray lances and other components you might need for your spray system, whether it is for surface treatment, cooling, lubrication, humidification - or to do something completely different. You know your process best, we know nozzles and industrial spray processes. Together we will find the right solution for you.

Below you will find answers to your questions about spray nozzles and spray systems. If you want our advice about what nozzles to use for your spray process, contact us and we will give you all the support you need.

Choose the right spray nozzle for an optimised spray process

Each type of spray nozzle has a specific flow rate, spray pattern and droplet size. To optimise the spray process, it is important to understand how different parameters affect the choice of spray nozzle and solution.

- What is the function of the spray nozzle and the spray process?Read the full answer

The first step when choosing the right spray nozzle is to define the function and application of the spray process, such as cooling a gas, washing a tank or flushing a conveyor belt. Type of spray nozzle, thus also spray pattern and droplet size, are important to consider in order to optimise the spray process.

- What surface should the spray cover? How should the nozzle be positioned?Read the full answer

The position of the nozzle over the target (D) and the area to be covered by the spray (B) are important to know in order to choose the right spray angle (A). The spray angle is measured near the nozzle orifice and the droplets are immediately affected by external forces such as gravity, air and gas flow.

- Desired flow rate? Available pressure?Read the full answer

Desired volume flow depends on the specific spray process. Most spray processes have general rules of thumb for flow ranges, but in many cases on-site testing is needed to achieve the right results.

- Which droplet size is most suitable for the spray process?Read the full answer

Droplet size is often critical in optimising a spray process. Many processes, such as gas cooling and gas scrubbing, depend on exposing the maximum total liquid surface area. The liquid then needs to be distributed in a large number of small droplets to create as much total surface area as possible. Other spray processes ...

- What type of liquid is used in the spray process?Read the full answer

A liquid's specific gravity, viscosity and the presence of particles affect the spray characteristics of the nozzle.

- Are there external factors affecting the nozzle spray?Read the full answer

Sometimes the spray is affected by external forces such as process gas flows, air flows or wind.

- Which material is most suitable for the spray process?Read the full answer

Listed below are a number of factors that should be considered when selecting materials for a specific nozzle. An incorrect choice of material is likely to affect the performance and life of the nozzle. We are happy to help and advise on which material is most suitable in your ...

- What are the benefits of an optimised spray process?Read the full answer

There are many factors to consider when selecting a nozzle for a specific spray process. An optimised spray process can make a big difference, contributing to: improved product and process quality increased production and reduced time for unplanned stops reduced maintenance costs lower operating costs by reducing the use of ...

Documents for download

Certifications

Here you will find our suppliers' various certifications. Some certificates are also available for downloading.

Support & technical advice

We offer the support you need to optimise your process, minimise risk and achieve a sustainable solution.

FAQ Spray nozzles & systems

Here you will find a variety of questions and answers about spray nozzles and spray systems.