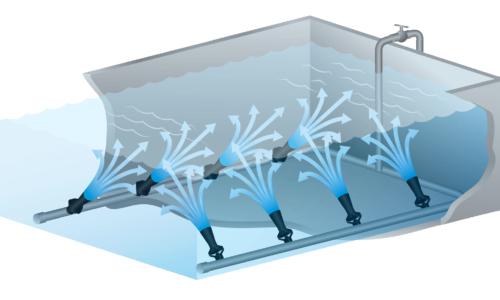

Stationary tank cleaning nozzles

Stationary tank cleaning nozzles, also known as static nozzles, have no moving parts, which means low maintenance. Stationary tank cleaning nozzles have a large free passage, ideal when the cleaning fluid contains particles. The nozzles are used in vessels up to Ø 5 m.

These specialised products include TW and the innovative HydroClaw®. The TW series' versatile size range and narrow shape ensure compatibility with small vessel openings, including bottles.

HydroClaw

- 119 - 442 l/min

- 360°

- Very large free passage

- Unique, compact design

- Patented

- Tanks up to Ø 3 m

TW

- 11.4 - 431 l/min

- 180°, 270°

- Energy efficient

- Compact design

- Large free passage

- Tanks up to Ø 3.6 m

CLUMP

- 28 - 470 l/min

- 360°

- Large free passage

- Tanks up to Ø 4.9 m (@ 3 bar)

LEM

- 15.9 - 839 l/min

- 360°

- Large free passage

- Tanks up to Ø 4.9 m (@ 3 bar)

Choose the right product for optimised tank cleaning

Choosing the right product is mainly determined by the type of media the tank contains and the diameter of the tank. In addition, there are a number of other factors to consider in order to achieve an effective tank cleaning process.

- Purpose of the tank cleaning process? Duration of the complete cleaning cycle?Read the full answer

A common answer is "A completely clean tank in as little time as possible." It is not always that simple though, there are several factors to consider in order to achieve effective tank cleaning. By optimally dimensioning the tank cleaning process, it is possible to increase ...

- What type of product does the tank contain?Read the full answer

Tank content characteristics will identify the amount of cleaning power required. The required cleaning force, toghether with the type of cleaning fluid used in the process, gives a good indication of which tank cleaning nozzle is most suitable for the process.

- Which cleaning fluid is used in the cleaning cycle?Read the full answer

Cleaning fluid characteristics will affect tank washer selection. Examples of cleaning fluid properties If the cleaning fluid is a solvent it can cause an explosive atmosphere in the tank, which requires an ATEX exempt tank cleaning nozzle.

- Vessel design and attributes? Are tank drawings available?Read the full answer

Vessel design is important when choosing the right tank cleaning equipment. Tank size and shape, together with other equipment inside and adjacent to the tank are important factors. A drawing can be of great help in designing and planning mounting points and installation of tank cleaning equipment.

- Available pressure and flow?Read the full answer

Once you have determined which type of tank cleaning nozzle is most suitable for your cleaning process, the next step is to determine the desired flow rate and nozzle size.

- What is the difference between various types of tank cleaning solutions?Read the full answer

Choosing the right tank cleaning nozzle for the cleaning process depends mainly on tank content and tank diameter. Both stationary and rotating spray devices are offered because one nozzle's operating principle and design could be more effective than the other depending on the application.

- What are the benefits of an optimised tank cleaning process?Read the full answer

Optimised tank cleaning can make a big difference and contributes to: improved washing results shorter washing cycles reduced water and chemical consumption lower temperature of the washing liquid easy maintenance higher process efficiency This in turn leads to time savings, reduced energy consumption and lower costs.

Previous projects

Read more about a selection of customised solutions and projects we have carried out for our industry colleagues and partners.

Right solution, delivered on time

Delivering the right solution on time requires co-operation, structure, attention to detail and following a process throughout the project.

FAQ Tank cleaning

Here you will find a variety of questions and answers about tank cleaning.