Spray nozzles & systems

Which droplet size is most suitable for the spray process?

Droplet size is often critical in optimising a spray process. Many processes, such as gas cooling and gas scrubbing, depend on exposing the maximum possible amount of liquid surface to a gas stream. The liquid then needs to be distributed into a large number of small droplets to create as large total surface area as possible. Other spray processes may require large droplets to achieve the desired outcome, for example when a flushing or cleaning a surface.

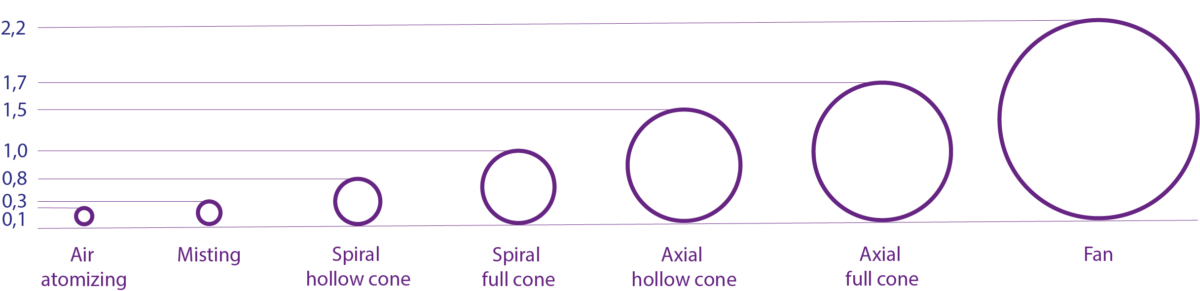

Different types of nozzles create relatively different droplet sizes

Correlation affecting droplet size

- higher pressure - smaller droplet size

- larger spray angle - smaller droplet size

- higher flow rate at a given pressure (nozzle size) - larger droplet size.

- when atomising using compressed air, the droplet size can be changed while maintaining the flow rate by varying the ratio of compressed air to liquid. The higher the air-to-liquid ratio, the smaller the droplet size.

Drop size distribution in the spray

A spray contains a wide range of different droplet sizes, which are measured in microns, i.e. one millionth of a metre. It is impossible to specify all droplet sizes in the spray, therefore the following definitions are used to describe the distribution of droplet sizes in the spray:

Volume Diameter

- Dv01 - 10% of the spray volume flow consists of droplets smaller than Dv01 and 90% of the volume flow consists of droplets larger than Dv01.

- Dv05 - is the diameter that divides the volume flow of the spray into two equal parts. Half of the total volume flow consists of droplets with a diameter less than Dv05 and the other half of the volume flow consists of droplets with a diameter greater than Dv05.

- Dv09 - 90% of the spray volume flow consists of droplets smaller than Dv09 and 10% of the volume flow consists of droplets larger than Dv09.

Sauter Mean Diameter

- D32 - the diameter of a droplet whose volume/area ratio represents the entire spray.

- Sauter Mean Diameter is one of the most used definitions to describe a spray in various process calculations.

Arithmetic Mean Diameter

- D10 - The average diameter of all the droplets in the spray.

Volume Mean Diameter

- D30 - The diameter of a droplet whose volume, if multiplied by the total number of droplets in the spray, equals the total volume.