EXAIR air knives

EXAIR air knives are designed to deliver efficient and quiet solutions for cleaning, drying and cooling using compressed air. The laminar airflow is distributed evenly and with high force along the entire air knife, ensuring optimal performance even at high pressure levels.

For applications with round, cylindrical or extruded surfaces, such as pipes, cables, hoses and wires, there are also round air knives that generate a smooth, efficient 360° airflow around the entire object.

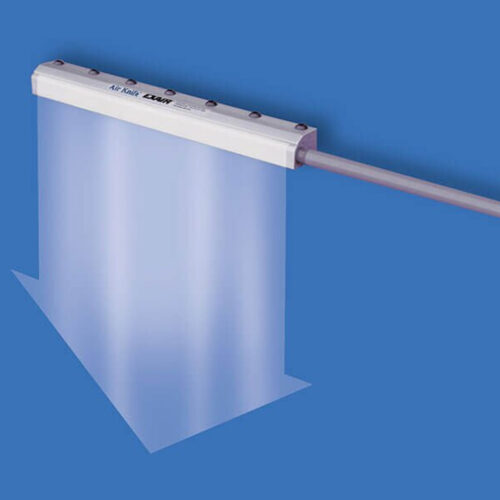

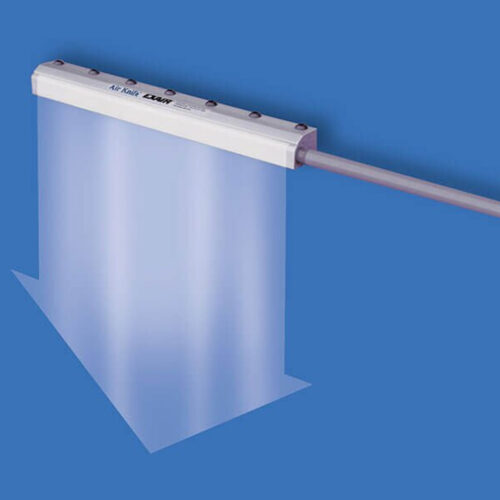

Super Air Knife

Quiet and powerful air knife with low compressed air consumption.

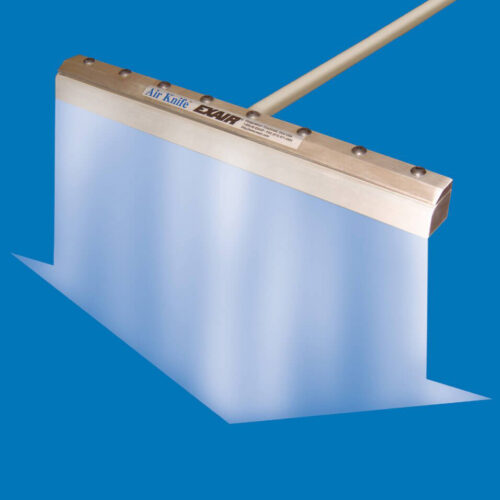

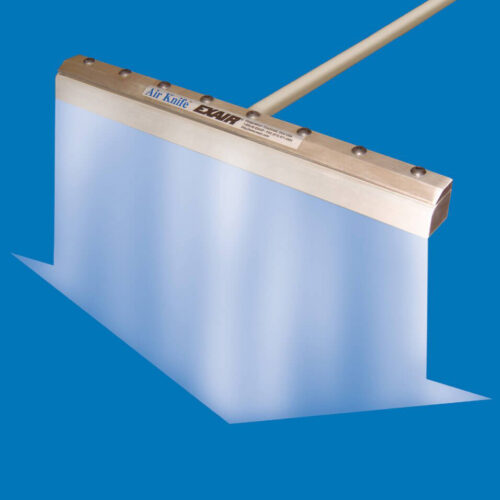

Standard Air Knife

Energy-efficient air knife with low noise level and compressed air consumption.

Full-Flow Air Knife

Low-cost air knife with full length airflow.

Super Air Wipe

Round air knife for environments with a temperature up to 425°C.

Standard Air Wipe

Air wipe for non-corrosive environments with a temperatures up to 65°C.

Which air knife is best for your application?

Here is a comparison of EXAIR's three different types of air knives - Super Air Knife, Standard Air Knife and Full-Flow Air Knife.

Super Air Knife

- Best choice for all types of applications

- Lowest operating cost

- Highest efficiency (lowest consumption of compressed air)

- The most quiet air knife

- Air amplification ratio 40:1

- Compressed air inlets on each end and at the bottom of the air knife

- Airflow length and overall length are the same

Standard Air Knife

- Good choice when a lower purchase price is desired

- Powerful and even airflow with high velolcity.

- Higher operating cost compared to the Super Air Knife

- Higher dBA rating compared to Super Air Knife

- Air amplification ratio of 30:1

- Compressed air inlets on each end of the air knife

- Overall length is 25 mm longer than the airflow length

Questions and answers on air knives:

- What material is an air knife made of?Read the full answer

EXAIR's Super Air Knives are available in the following materials: 6061 aluminium 303 stainless steel 316 stainless steel PVDF (polyvinylidene fluoride) EXAIR also manufactures Super Air Knives in PVC to order. Standard Air Knives and Full Flow Air Knives are available in: 6061 aluminium 303 stainless steel

- How does a Super Air Knife work?Read the full answer

Compressed air flows through an inlet (1) into the plenum chamber of the Super Air Knife. The flow is directed to a precise, slit-shaped opening. As the primary airflow passes out through the thin slit nozzle (2), it follows a flat surface that directs the airflow in a perfectly straight line. This creates a smooth air blade ...

- How does a Standard Air Knife work?Read the full answer

Compressed air flows through the inlet (1) into a plenum chamber. It is then choked through a thin nozzle (2) that runs along the entire length of the Standard Air Knife. This primary airflow follows the Coanda profile (3), which turns it 90° and directs the flow along the front of the unit. The primary flow immediately starts to drag along ...

- What air pressure should I use for the air knife?Read the full answer

The maximum allowable pressure for both the Super Air Knife and the Standard Air Knife is 17.2 bar. It is recommended to use the lowest pressure possible for the application in question. Always use a pressure regulator on the compressed air supply and increase the pressure gradually until the desired result is achieved.

- What lengths do you offer for Super Ion Air Knife and Standard Ion Air Knife?Read the full answer

We offer single piece lengths from 75 mm to 2740 mm for our Super Ion Air Knife, and from 75 mm to 1220 mm for our Standard Ion Air Knife. Customised lengths are also available. Contact us for help and more information.

- What is the recommended distance between the product and the round air knife?Read the full answer

For larger Air Wipe models (50 mm and above), a gap of approximately 13 mm is recommended between the outside of the material being processed and the inner diameter of the Air Wipe. Smaller models can have a narrower gap, as this allows secondary air to be drawn in around the object...

- At what pressure should I use a round air knife?Read the full answer

The maximum allowable pressure for Super Air Wipe is 17.2 bar. It is recommended to use the lowest pressure possible for the application in question. Always use a pressure regulator on the compressed air supply and increase the pressure gradually until the desired result is achieved.

- What is the angle of airflow from a round air knife?Read the full answer

The air leaves both the Air Wipe and the Super Air Wipe at a 60° angle of dispersion, which means that the air stream hits the material passing through the ring at a 30° angle. This design provides an effective wiping and cleaning effect around the entire perimeter of the object.

- How do I assemble a round air knife?Read the full answer

The Super Air Wipe can be mounted in several different ways. The most common method is to use the compressed air pipe as a support. Each half has internal NPT threads where the compressed air line can be screwed in. Place the Super Air Wipe in the desired position and then fasten the pipe firmly. An alternative mounting method is to ...

- What are the temperature limits for the air knives?Read the full answer

The Air Knives are designed to withstand different temperatures depending on the material and type of washer used. Below you will find the recommended temperature limits for each model: Aluminium Air Knife with plastic blade: up to 82°C Aluminium Air Knife with stainless steel blade: up to 205°C...

Contact one of our experts

Call, email or book a web meeting with one of our experts specialising in EXAIR Compressed Air Products. We will advise you on the most suitable product or solution in order to achieve an efficient and safe industrial process.

A short web meeting is usually a time-efficiently way to gather information to advise on the right product or solution. During a web meeting we can quickly and easily obtain information on the various factors that may influence the choice of equipment and solution to achieve the most effective result. Sometimes a site visit may also be a good idea, depending on your preference. Of course, you can also just call or email!

When suggesting a suitable product or solution we take into account - function, lifespan, quality, choice of material, and operating and maintenance costs. Our goal is to deliver a sustainable solution that creates added value for you as a customer.

Documents for download

Book a web meeting

Book a short web meeting with one of our experts to go through any questions you have about our products, applications or solutions.

Quick response time & technical support

We are available weekdays 08-16.30!

Knowledge base

We would like to share our knowledge and experience with you. In the Knowledge Bank you will find a variety of questions, explanations and process descriptions in our different product areas.