Spray nozzles & systems

What is the function of the spray nozzle and the spray process?

The first step when choosing the right spray nozzle is to define the function and application of the spray process, such as cooling a gas, washing a tank or flushing a conveyor belt. Type of spray nozzle, thus also spray pattern and droplet size, are important to consider in order to optimise the spray process.

Under Solutions our website lists a number of common applications and processes, as well as the nozzles that are recommended.

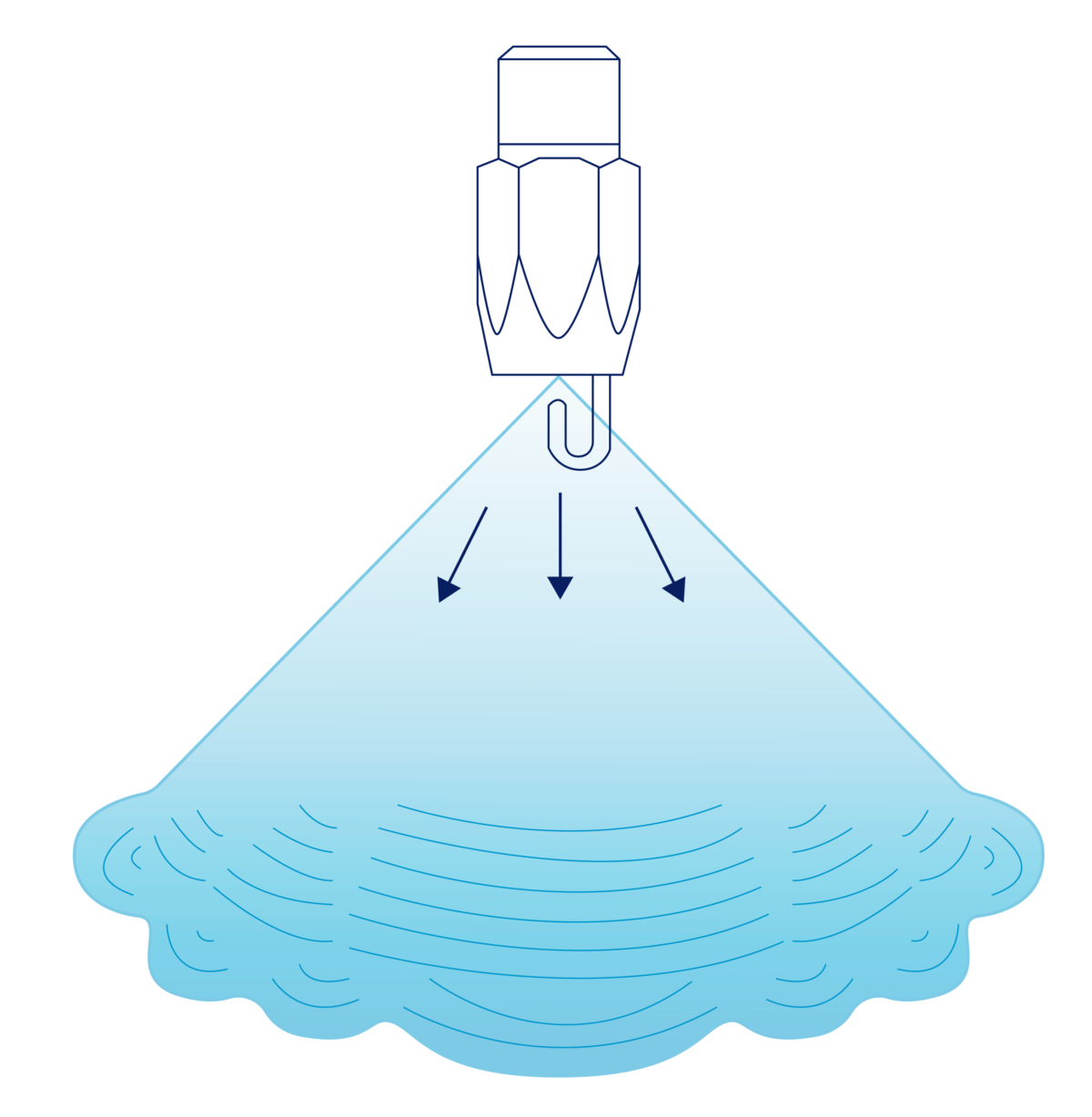

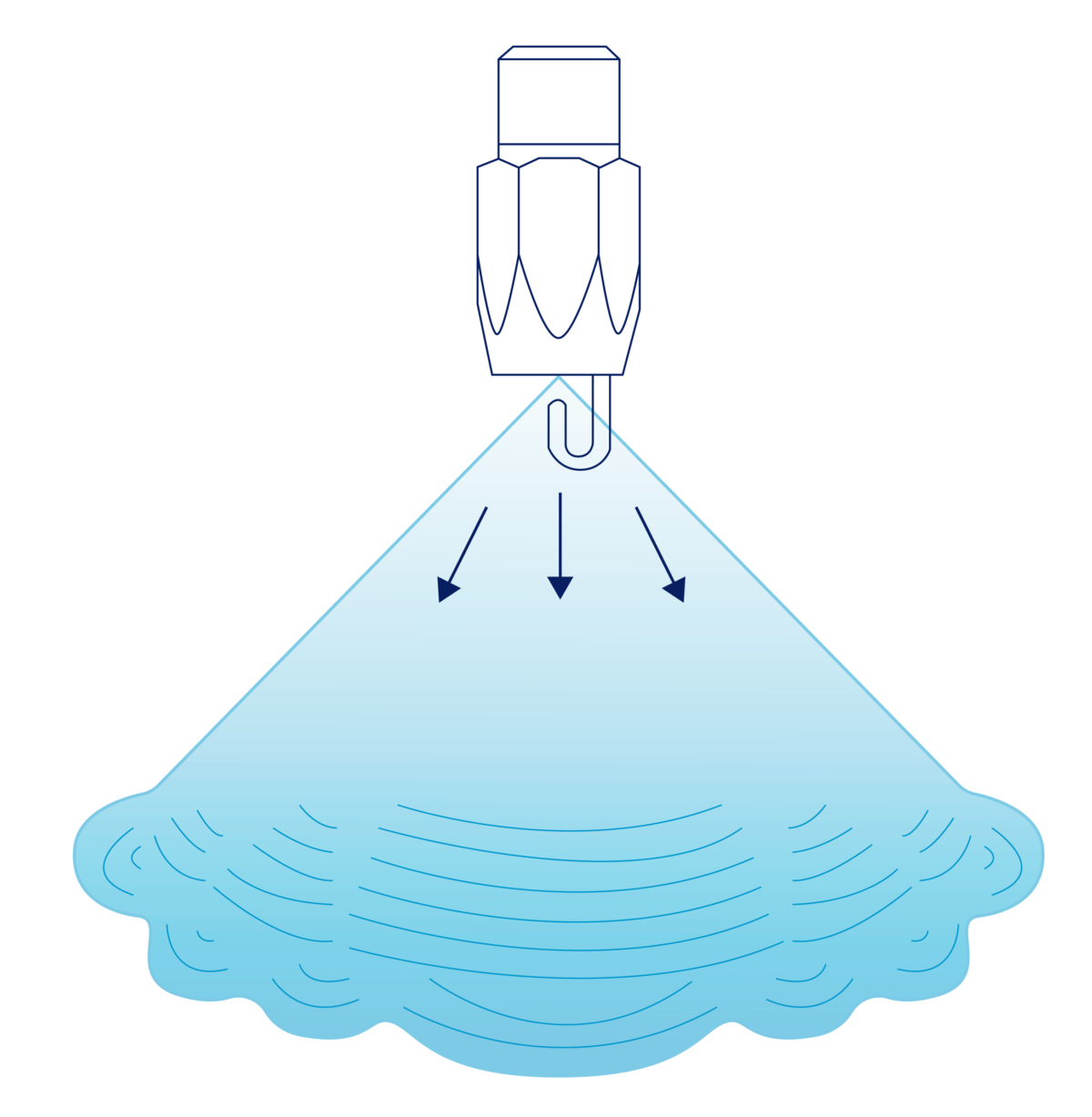

Full cone nozzles

The most common type of spray nozzle used in industry is the full cone spray nozzle. Applications include gas cooling, gas scrubbing, demister flushing, absorption, liquid distribution and fire protection.

There are three different types of full cone nozzles - axial, tangential and spiral nozzles. Compared with the spiral nozzle, the axial and tangential nozzle creates relatively larger droplets with a very even fluid distribution within the cone and across the surface, compared to the spiral nozzle. Axial and tangential full cone nozzles have a higher volume flow in the outer part of the cone and an even, lower flow within the cone. The spiral nozzle produces multiple concentric cones. These cones form two to three bands of relatively coarse droplets iwth higher flow, surrounded by wider bands of relatively fine droplets and lower flow.

Spiral full cone nozzle

- The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones.

- The cones form 2 to 3 bands of relatively large droplets, surrounded by wider bands of relatively small droplets.

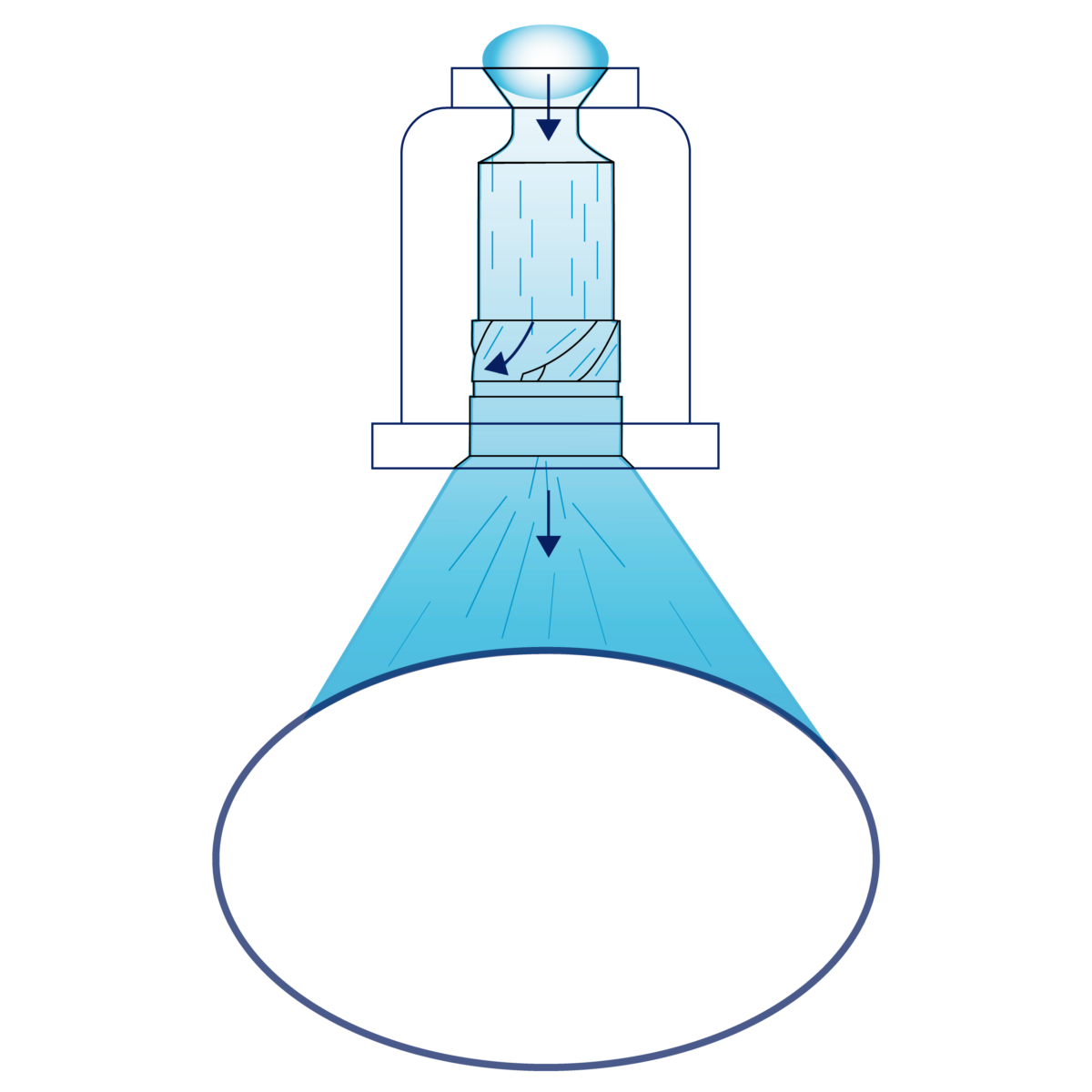

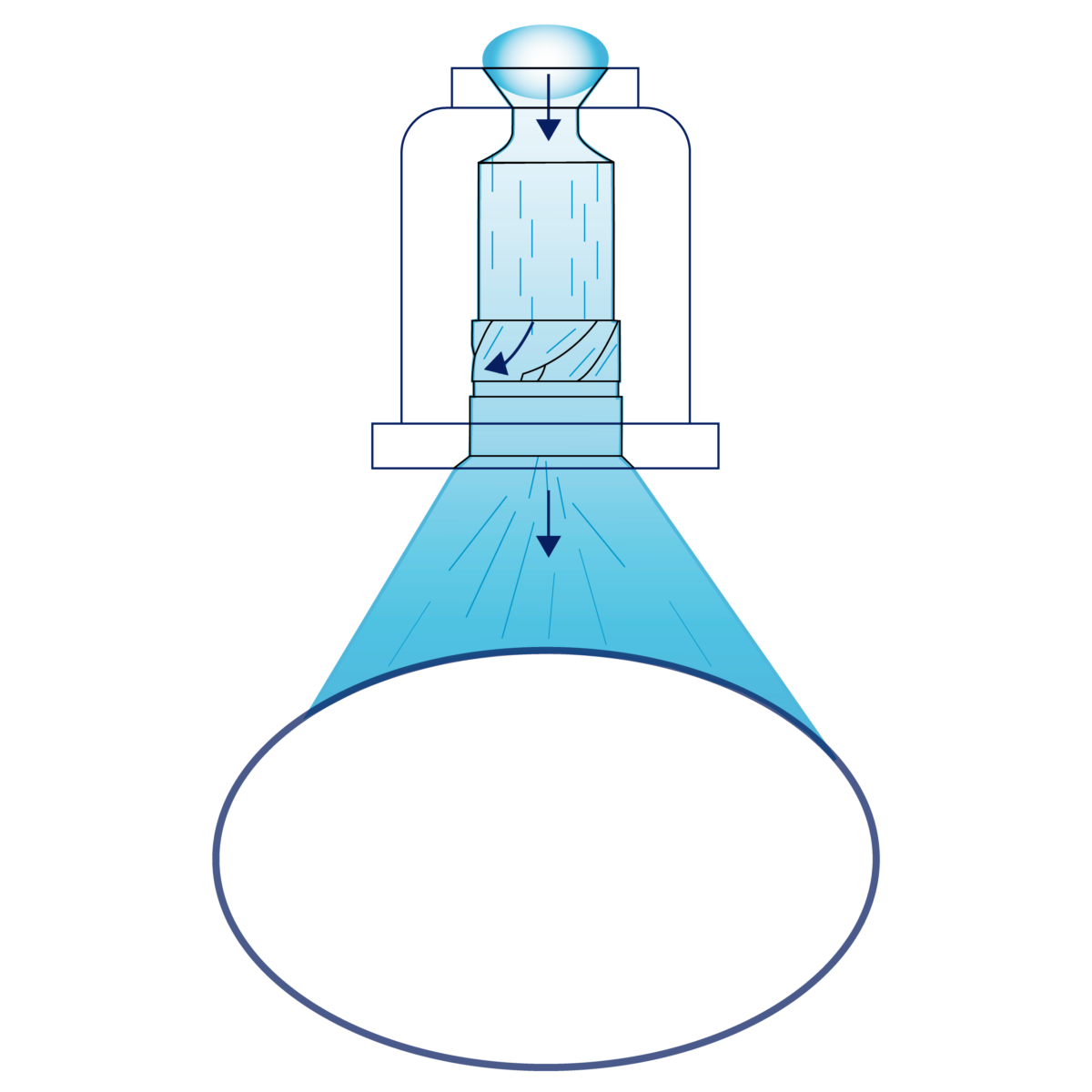

Axial full-console nozzle

- Spray exits on the same axis it enters

- Internal disc or vane causes the liquid to spin, and the centrifugal force exerted upon the geometry of the exit creates the spray pattern.

- Even distribution of droplets in the cone and across the surface

- Wide range of flow rates

- Large free passage

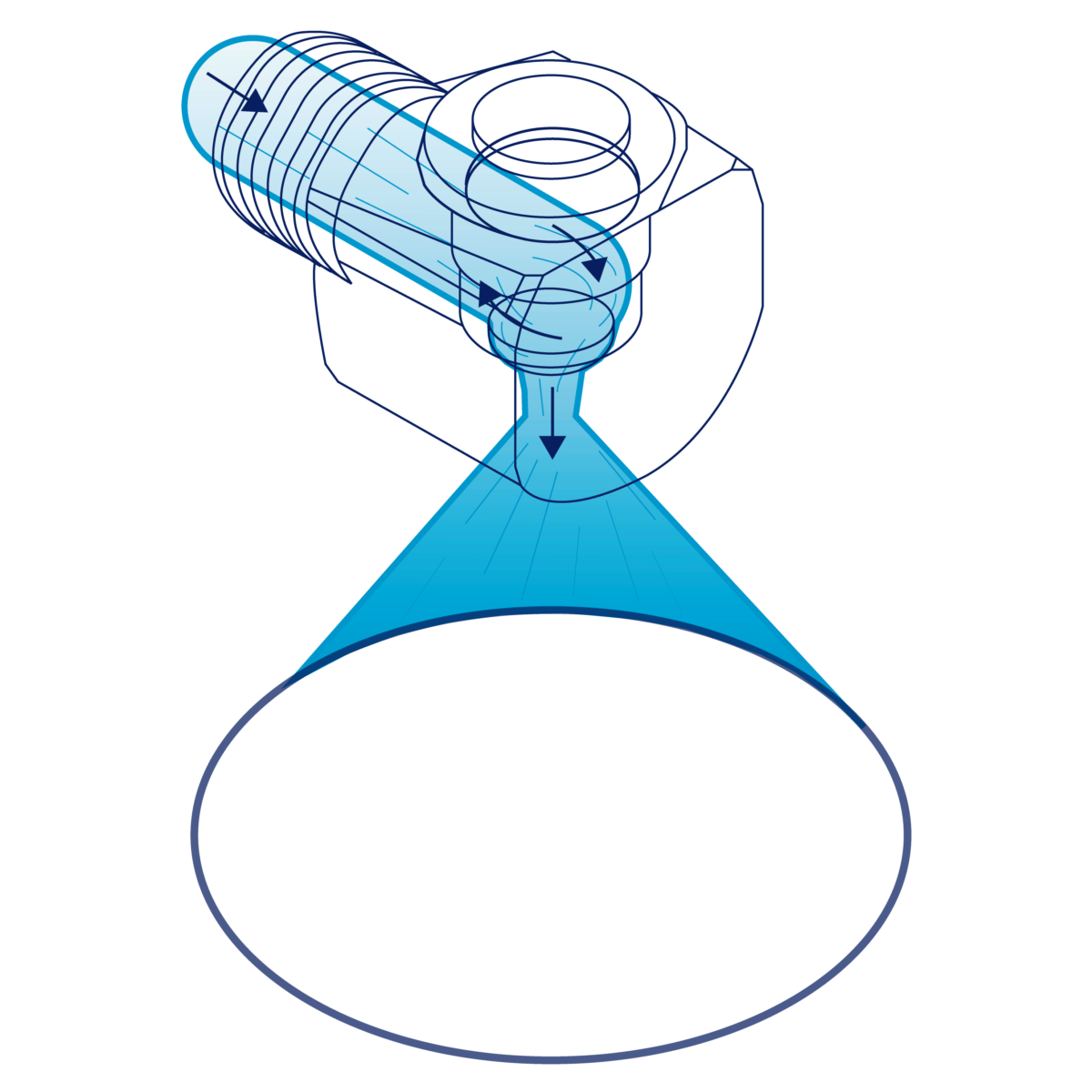

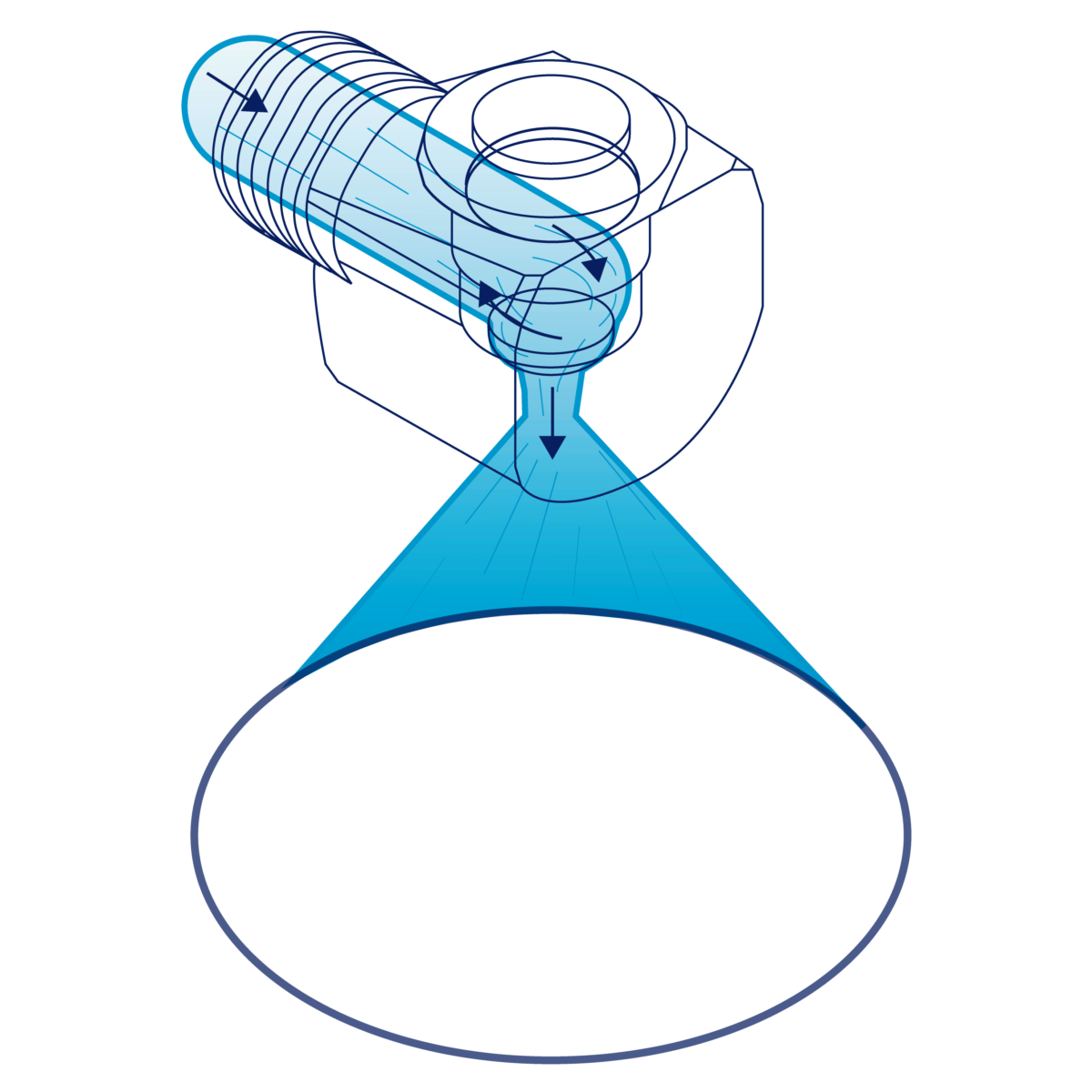

Tangential full cone nozzle

- Spray exits 90° from the entry axis

- Internal geometry creates the spray pattern by the liquid swirling around the body cavity before exiting the orifice

- Even distribution of droplets in the cone and across the surface

- Large free passage

Hollow cone nozzles

Hollow cone nozzles create relatively smaller droplets compared to full cone nozzles, which can be useful in for example gas cooling processes.

There are three different types of hollow cone nozzles - axial, tangential and spiral nozzles.

Spiral hollow cone nozzle

- The spray pattern is created by the liquid shearing along the spiral, forming a concentric cone.

- The spray is concentrated to the perimeter of the spray cone, which consists of relatively large droplets, whilst a fine mist is created within the cone.

Axial hollow cone nozzle

- Spray exits on the same axis it enters

- Internal disc or vane causes the liquid to spin, and the centrifugal force exerted upon the geometry of the exit creates the spray pattern.

- Spray is concentrated on outer edges of the cone.

- Relatively small droplets compared to axial full cone nozzles.

- Large free passage

Tangential hollow cone nozzle

- Spray exits 90° from the entry axis

- Internal geometry creates the spray pattern by the liquid swirling around the body cavity before exiting the orifice.

- Spray is concentrated on outer edges of the cone.

- Relatively small droplets compared to tangential full cone nozzles.

- Large free passage

Flat fan nozzles

Flat fan nozzles often create a high impact spray, with droplets that are relatively larger compared to other spray nozzles.

The flat fan nozzle is very effective for various flushing, rinsing and washing processes, but is also used to spray liquid over products and materials on conveyor belts.

Axial flat fan nozzle

- Uniform distribution with tapered edges

Deflector flat fan nozzle

- The spray is deflected off an external surface and creates an extra-wide fan spray pattern

Misting nozzles

Misting and fogging nozzles create a spray consisting of very small droplets even at low pressures and are used for dust control, humidification, cooling, surface treatment, and for spraying oil mist.

The higher the pressure, the smaller the droplets. Droplet size for misting nozzles ranges from 20 to 500 microns. Small droplets are ideal when full evaporation is required. It is important to note that the outlet opening is very small, which means that the nozzle can clog if the liquid contains solid particles. In order to prevent clogging, installing a pre-filter or using a misting nozzle with a built-in filter is recommended.

Small opening

- Liquid is atomised by being forced through a very small opening

- Narrower spray pattern at lower pressures

Impingement

- Liquid is atomised into a fine mist or fog when the laminar jet impinges on the pin.

- Spray angle 70° - 90°

Air atomising nozzles

Air atomising nozzles create a very fine spray of small droplets and are used for cooling, humidification, lubrication, surface treatment, etc.

The spray is created by mixing air with liquid in the spray process, thus creating relatively smaller droplets compared to other spray nozzles. The spray pattern is available as full cone, hollow cone, and flat fan.

This product group consists of a range of components, which can be combined in different ways to create the right drop size and flow for a particular application. Air atomising nozzles are also the best solution if you have a high viscosity fluid, where a 'regular' nozzle is undable to create small enough droplets.

Internal mixing

- Liquid and air are mixed in the nozzle and exit the nozzle through the same orifice.

- The streams are not independent; airflow changes will affect the liquid flow

- Not suitable for liquids with a viscosity above 200 cP.

External mixing

- Air and liquid exit the nozzle through two separate orifices.

- Air and liquid flow rates can be controlled independently, allowing precise metering of the liquid flow rate

- Suitable for all types of liquids, even above 200 cP.

Automatic nozzles

Spray nozzles and systems for intermittent spraying of liquids are used, for example, in the food industry and the pharmaceutical industry when high precision dosing is required or when a very expensive spray medium is used and spillage is to be avoided. The spray and dosage are controlled by means of electrical or pneumatic controls.

Pulse Width Modulation (PWM)

BETE's FlexFlow™ Spray Control System creates optimal spray precision by regulating the spray flow using Pulse Width Modulation (PWM). With traditional spray nozzles, the flow is adjusted by changing the fluid pressure, which in turn leads to a change in droplet size and spray pattern. PWM flow control creates a cyclical spray, i.e. on and off, up to 150 times per second. FlexFlow™ controls the fluid flow, with unchanged spray characteristics, without requiring a change in fluid pressure, creating a uniform, high-precision spray.

Tank cleaning nozzles

Spray pattern of tank cleaning nozzles ranges from 90° to 360° depending on the shape of the tank and the purpose of the tank cleaning. Different tank cleaning nozzles create different droplet sizes, which will affect cleaning impact.