EXAIR E-Vac vacuum generators for lifting

EXAIR E-Vac vacuum lifting systems consist of vacuum generators combined with vacuum cups in different models and dimensions. E-Vac vacuum lifting systems are designed to achieve maximum efficiency with minimum compressed air consumption.

Vacuum lifting systems are mainly used as pick-and-place robots in virtually all industries.

E-Vac® Low Vacuum vacuum generator

Effectively lifts porous materials such as cardboard and other fragile materials.

E-Vac® High Vacuum vacuum generator

For lifting non-porous materials such as glass, sheet metal, plastic, etc.

E-Vac® Adjustable Vacuum vacuum generator

Minimised compressed air use by adapting the vacuum level to lifting needs.

E-Vac® - Vacuum cups for vacuum lifters

Durable vacuum cups, ideal for handling lifting of various materials.

E-Vac® - Accessories

Accessories to easily create an efficient vacuum lifting system.

EXAIR E-Vac vacuum lifting system

EXAIR E-Vac vacuum lifting systems consist of vacuum generators combined with vecuum cups in different models and dimensions. In addition, a range of accessories is available, such as silencers, vacuum hoses, hose couplings and mounting clips.

EXAIR manufactures three different types of E-Vac vacuum generators Low Vacuum, High Vacuum and Adjustable Vacuum:

In-line E-Vac Low Vacuum - for porous materials

In-line E-Vac High Vacuum - for non-porous materials

Adjustable E-Vac - for both porous and non-porous materials.

Your specific application will determine which type of vacuum generator is most suitable.

The brochure below provides detailed information on how to assemble an EXAIR E-Vac vacuum lifting system.

Contact one of our experts

Call, email or book a web meeting with one of our experts specialising in EXAIR Compressed Air Products. We will advise you on the most suitable product or solution in order to achieve an efficient and safe industrial process.

A short web meeting is usually a time-efficiently way to gather information to advise on the right product or solution. During a web meeting we can quickly and easily obtain information on the various factors that may influence the choice of equipment and solution to achieve the most effective result. Sometimes a site visit may also be a good idea, depending on your preference. Of course, you can also just call or email!

When suggesting a suitable product or solution we take into account - function, lifespan, quality, choice of material, and operating and maintenance costs. Our goal is to deliver a sustainable solution that creates added value for you as a customer.

How do EXAIR E-Vac vacuum generators work?

EXAIR E-Vac vacuum generators are compact, simple and powered by compressed air. E-Vac vacuum generators are designed to achieve maximum efficiency with minimum compressed air consumption.

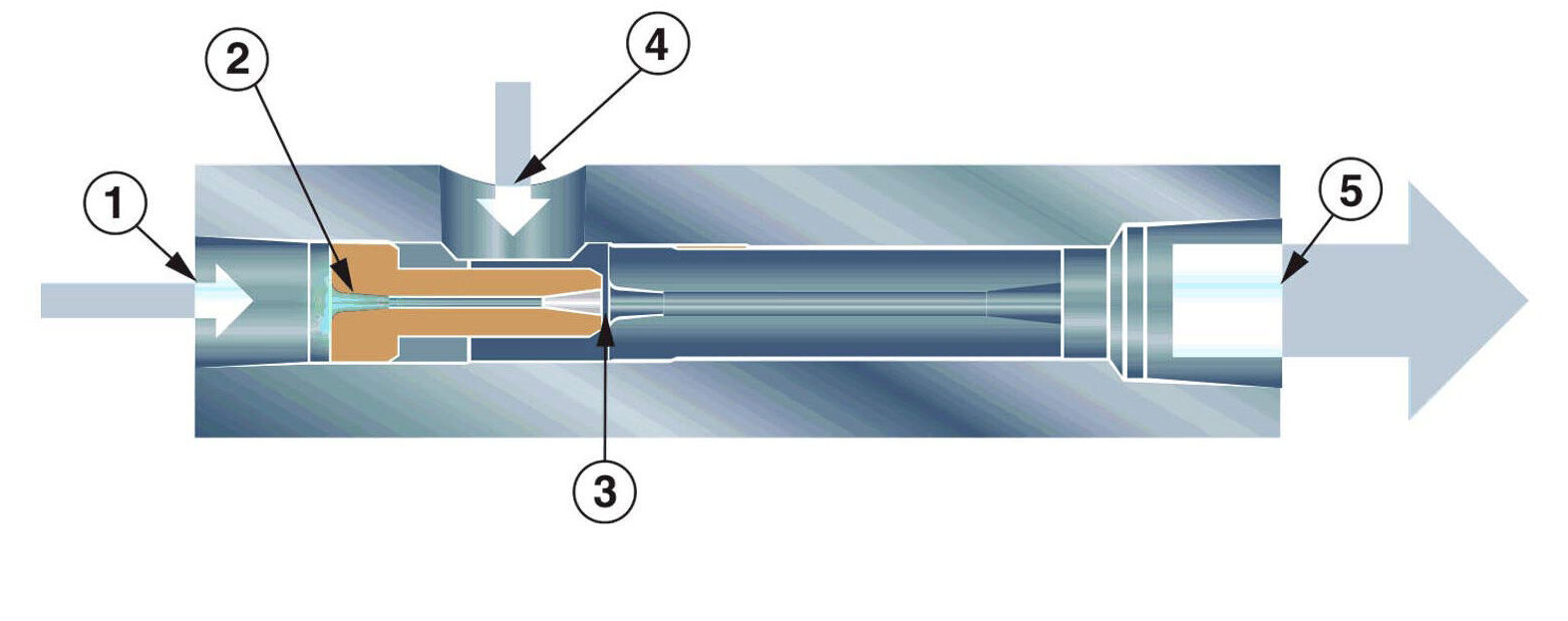

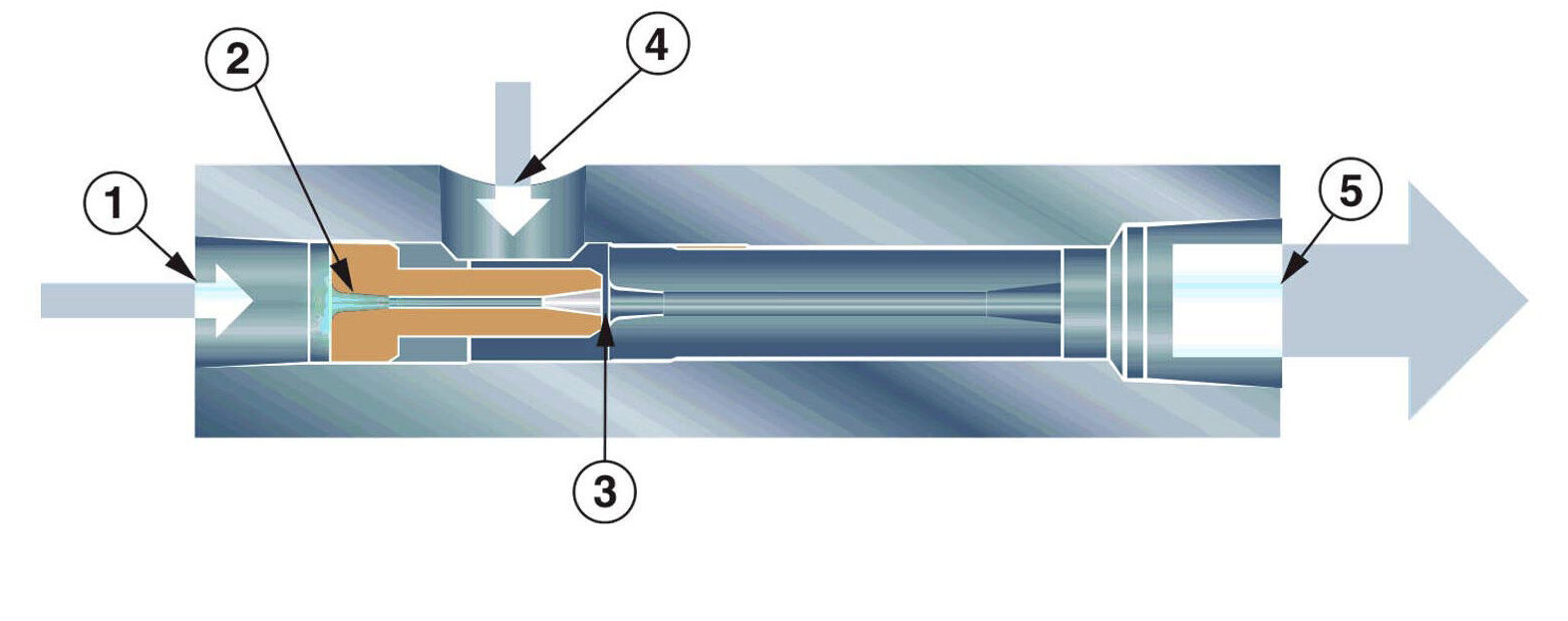

Compressed air flows through the inlet (1), then through a single directed nozzle (2). As the airstream exhausts, it expands and increases in velocity prior to passing through the venturi (3). A vacuum inlet tangential to the primary airflow (4) is located at the suction point between the orifice and the venturi. The airflow that is drawn through the vacuum inlet mixes with the primary airstream, then exhausts on the opposite end (5).

Documents for download

Book a web meeting

Book a short web meeting with one of our experts to go through any questions you have about our products, applications or solutions.

Quick response time & technical support

We are available weekdays 08-16.30!

Knowledge base

We would like to share our knowledge and experience with you. In the Knowledge Bank you will find a variety of questions, explanations and process descriptions in our different product areas.