Floating roof seals

HMT is a global leader in above ground storage tank solutions. Through a unique approach where we, together with HMT, work closely with our customers, we can bring a high level of innovation and service to the tank industry, with the aim of optimising tank operation.

HMT's complete storage tank product range includes external sealing systems, internal sealing systems, drainage and floating suction systems, geodesic domes, skin and pontoon type floating roofs, full contact floating roofs and emission reduction equipment.

Scissor Shoe Primary Seal

Mechanical bulkhead seal for external moving roofs. Effectively prevents gaps, copes with a wide range of edge spaces and is highly durable.

Sealmaster® Primary seal

Sealmaster consists of fully hardened compression plates that extend from the edge of the floating roof to the tank shell and down into the stored product.

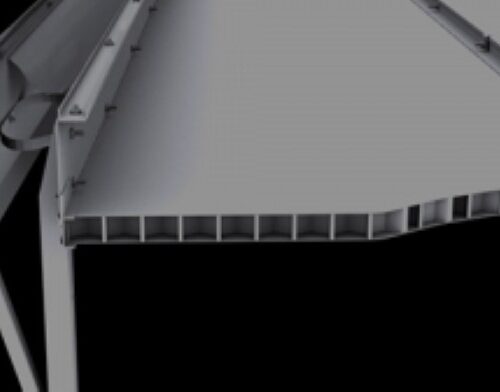

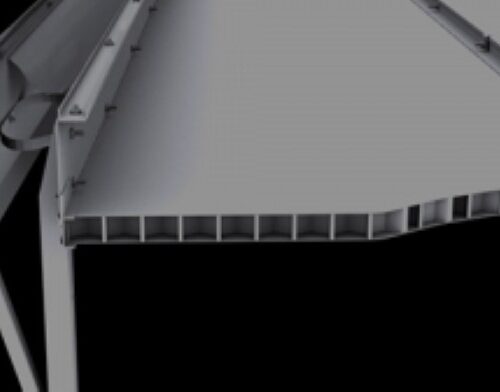

SM1 Primary seal | Heavy duty bucket lid edge seal

The SM1 Heavy Duty Shoe Plate Rim Seal is a fluid-mounted primary shoe plate seal with a secondary seal mounted on the shoe.

Econo-Flex® Secondary sealing

HMT Econo-Flex Secondary Seal is one of the most economical and efficient types of secondary seals on the market.

Flex-A-Seal™ secondary seal

HMT Flex-A-Seal Secondary Seal is one of the most economical and effective types of secondary seals available.

Seal King® Secondary sealing

The Seal King low profile secondary seal is specifically designed to provide the ability to maximise the usable volume of the tank

SealMaster® Secondary sealing

SealMaster floating roof sealant that adapts to the irregularities of edge spaces.

External secondary seal with scraper tip for floating roofs

The HMT Secondary Wiper Seal is a proven secondary seal that has been protecting storage tanks in the AST industry for over 40 years.

Mini-Shoe® Primary Shoe Seal

The Mini-Shoe Primary Shoe Seal for internal floating roofs is ideal for IFR applications and can be fitted to any type of roof.

Retro-Fit Mini-Shoe® primary seal

HMT Retro-Fit Mechanical Shoe Seal is developed to solve how to install a primary mechanical shoe seal on an existing lightweight aluminium IFR

ALLENTECH Primary Shoe Seal

The primary mechanical shoe seal is considered a fluid-mounted seal according to API and EPA recommendations.

Vaporflex® Internal Secondary Sealing

The Vaporflex Internal Secondary Seal is an effective, durable and flexible secondary seal that is compatible with almost all stored products.

ALLENTECH Secondary Shoe Seal

ALLENTECH's stainless steel secondary mechanical bulkhead seal for aluminium internal floating roofs.

Wax scrapers

HMT's wax scrapers manage environmental risks and improve the safety of aboveground storage tanks.

- Vessel design and attributes? Are tank drawings available?Read the full answer

Vessel design is important when choosing the right tank cleaning equipment. Tank size and shape, together with other equipment inside and adjacent to the tank are important factors. A drawing can be of great help in designing and planning mounting points and installation of tank cleaning equipment.

- What is the objective of replacing the tank storage equipment?Read the full answer

The reasons for changing the tank storage equipment is important to know in order to ensure that the most optimal solution and the right type of product is supplied. Improved efficiency, i.e. reduced emissions, leads to less environmental impact but also reduced loss of product, which means lower costs. ...

- What is the difference between various types of tank cleaning solutions?Read the full answer

Choosing the right tank cleaning nozzle for the cleaning process depends mainly on tank content and tank diameter. Both stationary and rotating spray devices are offered because one nozzle's operating principle and design could be more effective than the other depending on the application.

- Purpose of the tank cleaning process? Duration of the complete cleaning cycle?Read the full answer

A common answer is "A completely clean tank in as little time as possible." It is not always that simple though, there are several factors to consider in order to achieve effective tank cleaning. By optimally dimensioning the tank cleaning process, it is possible to increase ...

- What other factors may be important when changing tank storage equipment?Read the full answer

Other factors to consider when replacing tank storage equipment may include: Timeframe for emptying and any repair work on the existing tank Manufacturing and delivery time Installation - How much time is estimated for installation? Is an on-site supervisor required? The sealing solution has a ...

- What are the benefits of choosing the right product for optimised tank cleaning?Read the full answer

Optimised tank cleaning can make a big difference and contributes to: improved washing results shorter washing cycles reduced water and chemical consumption lower temperature of the washing liquid easy maintenance higher process efficiency This in turn leads to time savings, reduced energy consumption and lower costs.