Ammonia stripping

Process water and wastewater from industries, biogas plants and municipal treatment plants contain ammonium ions (NH4+) and ammonia gas (NH3), which has a negative impact on water quality, ecosystems and human health.

Ammonia stripping with air or vapour is a safe and cost-effective process to easily remove contaminants.

How does ammonia stripping work?

Process water and wastewater contain ammonium ions (NH4+) together with dissolved ammonia gas (NH3):

NH4+ + OH– ↔ NH3 + H2O

- pH <7 ⇒ virtually all ammonia will be soluble ammonium ions (NH4+)

- pH >12 ⇒ virtually all ammonia will be dissolved gas (NH3)

- in the pH7 to pH12 range, both NH4+ and NH3 are present in the process water or wastewater

- the amount of dissolved gas (NH3) increases with temperature and pH

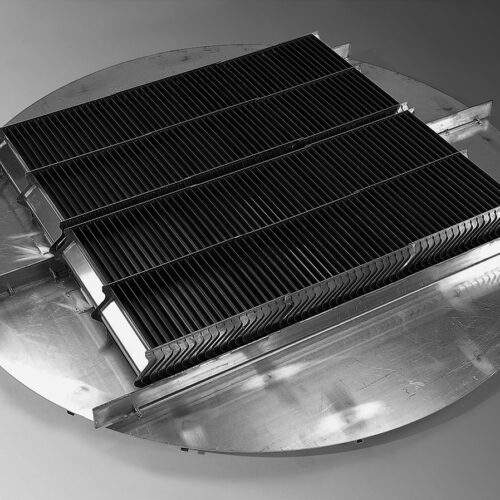

The process of removing ammonium ions and dissolved ammonia gas from the wastewater is achieved in a packed column, where the function of the packed bed is to increase the liquid-gas contact area.

Before introducing the contaminated water into the column, the temperature is adjusted and the pH is raised (by adding NaOH or lime) to increase the proportion of NH3 in the process water or wastewater.

The influent stream is introduced at the top of the packed bed and flows down through the column. Countercurrent to this, air or steam flows up and strips ammonia from the liquid phase. Ammonia-laden off-gases exit the top of the column and treated water is collected in the column sump.

Air vs steam stripping

In general, air stripping means lower operating costs compared to steam stripping and is a good option when steam or cooling water is not available in the operation.

Steam stripping, on the other hand, is a more effective method for removing ammonia contaminants.

Which process parameters are important when designing a stripper column?

The following parameters are important to consider when deciding whether ammonia stripping should be carried out using air or steam:

- Process-specific conditions

- Temperature

- Ammonia - concentration, pH value

- Other contaminants or pollutants?

- Energy source

- Is it possible to re-use removed contaminants? Commercial value?

- Do the off-gases need to be treated in order to reduce emission?

Project review and proposed solution

To deliver the optimal solution, it is important to go through in detail various factors that affect product choice, type of solution, investment objective, and other requirements at an early stage of the project.

A start-up meeting is important to find out about various factors that will affect choice of equipment and solution in order to achieve the most efficient and sustainable solution. We are happy to set up the start-up meeting as a web meeting or a site visit, depending on your preference. All details and information from the start-up meeting we will summarise and go through with you to make sure we agree on project scope and objective.

Next step, we present a proposed solution, focusing on function, lifespan, quality, choice of material, operating and maintenance costs, and environmental impact. Our goal is to deliver a sustainable solution that creates added value to your company,