Fire protection - Water mist

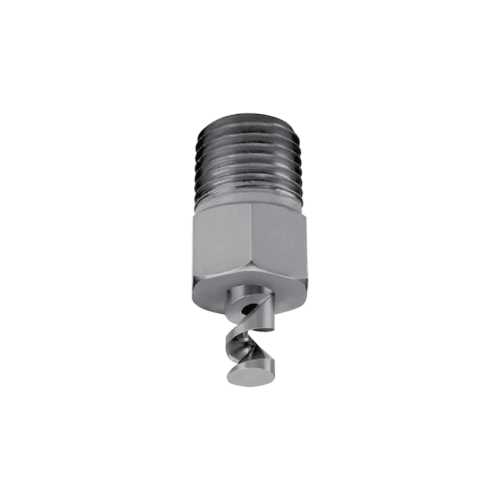

Misting nozzles are used to extinguish or control fires by spraying fine droplets onto the flames, which rapidly evaporate, cool, and displace oxygen.

How does a water mist fire protection system work?

Fire protecion systems with misting nozzles can effectively fill a contained area with the fine water droplets. The heat of fire easily vaporises the low volume flow and high evaporation rate of water mist sprays. These absorb heat and displace oxygen, which suppresses the fire whilst minimising damage to water-sensitive equipment or other assets that would otherwise be destroyed by water damage in high flow deluge systems.

Factors to consider for effective water mist fire protection

There are a number of important factors to consider in order to achieve an optimised fire protection solution. Our experienced staff and engineers are available to help with calculations and find the right solution.

- Size and shape of the target area, equipment, or enclosure

- Design specifications and requirements - required flow rates/coverage densities

- Available nozzle mounting locations

- Available pressure drop (∆P) = supply pressure at the nozzle inlet. minus process pressure outside nozzle

Project review and proposed solution

In order to ensure that we deliver the optimal solution, it is important to carefully review the various factors that affect the choice of solution and product, the objective of the investment, and any requirements and wishes early on in the project.

A start-up meeting is important to find out about various factors that will affect choice of equipment and solution in order to achieve the most efficient and sustainable solution. We are happy to set up the start-up meeting as a web meeting or a site visit, depending on your preference. All details and information from the start-up meeting we will summarise and go through with you to make sure we agree on project scope and objective.

Next step, we present a proposed solution, focusing on function, lifespan, quality, choice of material, operating and maintenance costs, and environmental impact. Our goal is to deliver a sustainable solution that creates added value to your company,