Random packings

We offer random packings designed to optimise the contact area between gas and liquid, with lowest possible pressure drop.

When selecting random packings, the aim is to optimise the contact surface between gas and liquid, with lowest possible pressure drop. Random packings are used in various heat or mass transfer processes. Important factors to consider include flow capacity, temperature, material selection and total packing bed height.

Hiflow® Ring

High performance random packing with high mechanical stability, very high void fraction and low pressure drop.

Raflux Ring

Standard random packing with an open structure ensuring a regular flow through the packing, lowering the pressure drop.

RMXR Ring

Patented latest generation random packing in metal, with very high performance and an increased capacity of up to 25% compared other packings.

RMSR Ring

Standard packing in metal with excellent mass transfer efficiency and high mechanical stability, whilst maintaining a very low pressure drop.

HiDur® Inert Balls

Simplest design of all types of random packings, with relatively small surface area per bed volume, low void fraction and high pressure drop.

Saddles

Standard random packing that is widely used in the chemical industry due to its excellent mechanical properties and corrosion resistance.

Hiflow® Saddles

A new and improved version of standard Saddles, with lower pressure drop and increased surface area.

Cylindrical Ring

The most basic type of standard random packing, available in a variety of materials and thicknesses.

Choose the right column internals for an optimised process

To maximise process efficiency in a column it is important to understand how various parameters affect choice of equipment and type of solution.

- Which are the underlying principles of mass and heat transfer?Read the full answer

Mass transfer Many industrial processes generate mass transfer of some sort, i.e. moving mass from one part of the process to another. This may be to separate different substances from each other, change the composition of a mixture, or concentrate a solution. Mass transfer can take place in a number of ...

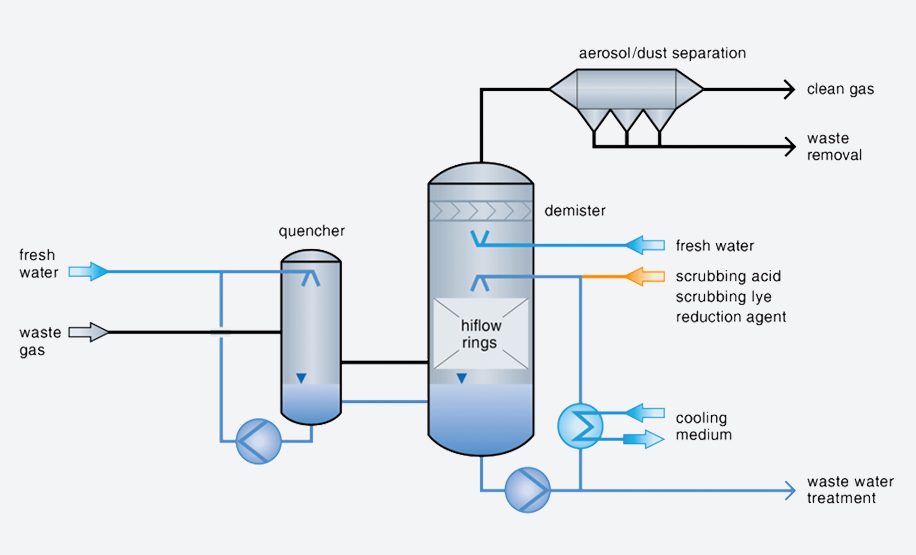

- How does flue gas cleaning work? Key process parameters?Read the full answer

Flue gas cleaning is a mass transfer process with an objective to remove unwanted or hazardous substances from the process. Flue gas cleaning is used in a variety of industries and applications.

- How does flue gas condensation work? Key process parameters?Read the full answer

Flue gas condensation is a process commonly used in the chemical industry and is an example of heat transfer. Flue gas condensation is used to recover and reuse heat produced during a process.

- How does stripping work? Key process parameters?Read the full answer

Stripping is a mass transfer process where one or more substances are removed from a liquid. One of our areas of expertise in mass and heat transfer is the removal of ammonium or other volatile substances and contaminants in process or waste water.

- What support does Hansa Engineering offer to optimise mass and heat transfer processes?Read the full answer

We have a lot of experience and solid know-how regarding mass and heat transfer processes and work closely with our supplier RVT Process Equipment's engineering and technical support department. ...

Technical support, engineering and know-how

We have a lot of experience and solid know-how regarding mass and heat transfer processes and work closely with our supplier RVT Process Equipment's engineering and technical support department.

Together we offer extensive process knowledge and experience, focusing on developing an optimised and sustainable solution for our customers.

Technical support and advice

- hydraulic analysis - selecting the right type of packing

- technical solutions for customer-specific problems, applications or column equipment

Call, email or book an online meeting! We are also happy to make a site visit, if needed.

Advanced technical support

- Process analyses - Process optimisation, cost savings, troubleshooting

- Engineering - Engineering, CFD analysis (calculations of pressure drop and flow for column optimisation), FEM analysis, mechanical strength analysis.

- Hydraulic and mechanical analyses - Hydraulics, maldistribution, bottlenecks, etc

- Test facilities - Test column for packings, test column for mass transfer trays, test facility for liquid distributors. RVT also offers test facilities on customer site.

Contact us for more detailed information.

Previous projects

Read more about a selection of customised solutions and projects we have carried out for our industry colleagues and partners.

Right solution, delivered on time

Delivering the right solution on time requires co-operation, structure, attention to detail and following a process throughout the project.

FAQ Column internals

Here you will find a variety of questions and answers about column internals.