Cleaning tanks and vessels

We deliver solutions for cleaning tanks and vessels, focusing on efficient cleaning results, shorter wash cycles, optimisation of water, chemical and energy consumption, and easy maintenance. This means you can save time, reduce energy consumption and lower your costs.

The best solution for efficient cleaning of tanks and vessels depends on a number of different factors, which you can read more about below.

'A completely clean tank in as little time as possible'

When 'What is the purpose with the tank cleaning process?' is asked, a common answer is "A completely clean tank in as little time as possible." But it is not always that simple. There are several factors to consider in order to achieve effective tank cleaning. By optimally dimensioning the tank cleaning process, you will be able to clean your tanks more efficiently. It will reduce the amount of cleaning agents used, save time and reduce your overall costs.

As a first step you need to consider these questions:

- Does the tank need to be 100% clean or is it suffient to rinse the tank between batches?

- Should the whole tank be cleaned or only part of it?

- Should product be recovered from the tank?

- Is the duration of the cleaning cycle important?

The way the tank cleaning process is optimised and how to select the most suitable product depends on your type of business, the process and any specific requirements. Here are a couple of examples:

Example 1

Blue colour is produced in a process tank and the same blue colour is always made in the tank. There is a short time between batches, so the remaining colour does not have time to dry.

In this case, there is no need to clean the tank to 100%, as a small amount of residual colour will not affect the next batch. It may therefore be sufficient to simply rinse the tank between batches. For maximum process efficiency, the time between batches in this example may be more important than the washing result itself.

A tank cleaning nozzle with a short rinse cycle and minimum fluid consumption may be suitable for this specific process.

Example 2

The tank contains a high value pharmaceutical or chemical product. There is a risk that the product may ignite when it dries. Only when the product is damp or wet is it stable.

In such a circumstance it might be that product recovery of the high value residue left in the tank is very important. It might also be vital to ensure that after the initial production process is finished, the cleaning device needs to use very low volumes of liquid to keep the remaining residues damp to prevent any explosion risk.

A tank cleaning nozzle with low liquid consumption makes it less costly to recycle the product. In this example, the tank cleaning nozzle fulfils two functions in a single wash cycle.

What type of product does the tank contain?

Tank content characteristics will identify the amount of cleaning power required. The required cleaning force, toghether with the type of cleaning fluid used in the process, gives a good indication of which tank cleaning nozzle is most suitable for the process.

Some of the main considerations regarding tank content are:

- Is the product easily soluble?

- How sticky is the product?

- How viscous is the product?

- Toxic? Corrosive? Explosive?

- How valuable is the product? Is it recyclable?

- Does the product change properties when wet or dry?

- How quickly does the product need to be removed from the tank?

Sometimes choosing the right type of tank cleaning nozzle is relatively simple. If the product in the tank is easily soluble, a static or rotating tank cleaning nozzle is a good choice. However, if the product is very sticky and viscous, a jetting tank cleaning machine might be the best solution.

In other cases, the choice is less obvious. For example, the speed of product removal might be very important due to the nature of the product. If the product dries very hard (e.g. a resin) and impossible to remove once it has dried, it is vital to remove the product as quickly as possible. In this case it is important to choose a tank cleaning nozzle or machine that can complete the entire wash cycle before the product has dried.

Which cleaning fluid is used to clean the tank or vessel?

Cleaning fluid characteristics will affect tank washer selection.

Examples of characteristics

- If the cleaning fluid is a solvent it can cause an explosive atmosphere in the tank, which requires an ATEX exempt tank cleaning nozzle.

- Cleaning fluid with high viscosity affects flow and pressure, which in turn should be taken into account when selecting a suitable tank cleaning nozzle.

- If the cleaning fluid dissolves the product easily only a low-power tank cleaning nozzle is required. However, if the cleaning fluid will need some power to do its job, then a jetting unit will be more appropriate.

- To make the cleaning process more efficient, cleaning fluids are sometimes used at high temperatures, which may affect the choice of tank cleaning nozzle.

- Sometimes different cleaning fluids might be used at different stages of the cleaning cycle. Therefore it is important that the tank washer chosen can function correctly with all types of fluids used.

Materials of construction

- Some chemicals present in the cleaning fluid can affect seals, bearings and other components/materials. A highly acidic atmosphere will affect stainless steel. Hastelloy would therefore be more appropriate.

- High temperatures can affect the material, leading to major problems. Special attention should be paid to products made of certain plastic materials.

- Food grade products require specific surface finish requirements and the tank cleaning nozzle needs to fulfil these requirements.

Cleaning fluid particles

- If the cleaning fluid contains particles, you might need a pre-filter. Or, a tank cleaning nozzle designed to cope with particles in the cleaning fluid could be a good alternative.

Vessel design and attributes

Vessel design is important when choosing the right tank cleaning equipment. Tank size and shape, together with other equipment inside and adjacent to the tank are important factors. A drawing can be of great help in designing and planning mounting points and installation of tank cleaning equipment.

Tank size and shape

Diameter and height

The diameter is important to ensure that the tank cleaning nozzle can generate sufficient throw length and force/energy to clean the tank surface effectively. The height is also important, the distance must not be too large. Two tanks with the same diameters but different heights, may require two completely different solutions to achieve the desired result.

Shape

The vessel could be designed in a way that the angle of the nozzle jets agianst the tank surface greatly varies, which in turn may affect the cleaning result in different parts of the tank.

Equipment inside and adjacent to the tank

Baffles, mixers, agitators, pipes, etc. inside the tank affect which type of tank cleaning nozzle to choose, as well as the number of nozzles required to achieve a good result. It is also important to know the optimal nozzle placement/mounting point.

Agitators and mixers

If an agitator is installed in the centre of the tank, two tank cleaning nozzles are often required, one on each side of the agitator. Sometimes it is also useful to install additional static nozzles to ensure that hard-to-reach areas of the tank are cleaned.

Baffles

Baffles often create problems with shadows and the best solution is to install several tank cleaning nozzles in the tank.

Pipe connections and tank opening

The number and size of pipe connections, as well as the size of the tank opening, is important to consider as it affects which nozzle type and size to choose.

Tank drainage

Tank drainage-by-gravity rate is important to know in order pevent liquid form rising during cleaning. Ensure that the drain can handle whatever fluid volume enters the tank. An accumulation of cleaning liquid at the bottom of the tank, will affect the cleaning result.

What is the difference between various types of tank cleaning nozzles?

Choosing the right tank cleaning nozzle for the cleaning process depends mainly on tank content and tank diameter. Both stationary and rotating spray devices are offered because one nozzle's operating principle and design could be more effective than the other depending on the application.

Stationary tank cleaning nozzles

Stationary tank cleaning nozzles

- contain no moving parts

- large free passage, which is an advantage if the cleaning liquid contains particles

- very low maintenance

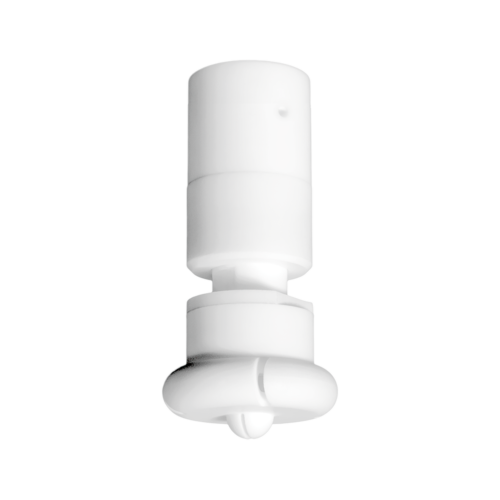

Rotating tank cleaning nozzles

Rotating tank cleaning nozzles

- use the spray media’s reaction force to drive nozzle head rotation

- increased tank washing efficiency over static spray balls, saving time and money by reducing water and cleaning agent consumption while decreasing downtime

Tank cleaning machines

Tank cleaning machines

- high impact and effective cleaning

- suitable for large tanks or when the tank product is difficult to remove

- use the spray media flowing through internal gears on the body to rotate sets of high-impact jet nozzles through an efficient 2-axis orbital pattern, providing a 180°- 360° coverage

Mechanical cleaning

Effective tank cleaning requires large droplets hitting the the tank wall surface at a high speed. Both rotating tank cleaning nozzles and tank cleaning machines generate this type of spray. When large droplets hit the surface at high speed, it mechanically removes any residual product not dissolved by the cleaning fluid.

The distance between the spray head and the tank wall, together with operating pressure, are important factors for effective mechanical cleaning. If the distance between the spray head and the tank wall is too great, the cleaning power (and the cleaning result) is reduced. If the operating pressure is too high, the large droplets are atomised into smaller droplets, which in turn leads to an inferior cleaning result.

Using greater mechanical force in the tank cleaning process makes it possible to shorten the cleaning cycle, lower the washing fluid temperature, and reduce the need for chemicals. The illustration below shows an example of the mechanical cleaning force of a static spray ball compared to a rotating tank cleaning nozzle.

Static spray ball

Rotating tank cleaning nozzle

Rotating tank cleaning nozzles have a higher mechanical cleaning impact compared to static spray balls, resulting in shorter cleaning cycles, higher efficiency and cost savings.

Spray coverage

Listed below is spray coverage (m) for our complete range of tank cleaning nozzles.

Available pressure and flow?

Once you have determined which type of tank cleaning nozzle is most suitable for your cleaning process, the next step is to determine the desired flow rate and nozzle size.

Pressure and flow

Desired pressure and flow rate have often already been limited by the plants existing tank cleaning setup. If this is the case, flow rate and pressure at the cleaning head need to be specified. This should not be based on the pump, or the theoretical flows and pressures. It should be physically measured at the head. Unfortunately, in some cases it is not possible, and it may need to be “Guestimated”. This means that pump output has to be specified, along with the pipe lengths, diameters etc. This will give a good indication of what is reaching the head, but is no substitute for real measurements at the cleaning head.

If there is insufficient flow and pressure to use the optimum cleaning head or heads, then alternative solutions will be required. It may be possible to simple change the delivery pump, or add in a buffer tank for increased delivery, or it may be that a different tank cleaning nozzle or multiple units can solve the problem.

However, changing the tank washers in an existing set up, or changing the delivery pump for inlet flow may also have consequences on the outgoing flow. If a scavenge pump is used to remove liquid from the tank, then the settings on this pump need to be changed in accordance with the inlet flow. If not, excess pooling may occur in the tank and inhibit the cleaning action of the tank washer.

Recommended flow rate

In general, tank cleaning nozzle rotating speed is affected by pressure. The higher the rotation speed, the more likely it is that the rotating nozzle will atomise the droplets so that they become much smaller. This leads to reduced cleaning impact. It is therefore important that a tank cleaning nozzle or machine is used within the recommended flow rate range.

Cleaning fluid chemical properties

Changing the cleaning liquid can affect pressure and flow rate due to a different liquid viscosity.

Cleaning fluid particles

If cleaning fluids are being reused filtration might be required, which in turn could affect pressure and flow rate.

Project review and proposed solution

To deliver the optimal solution, it is important to go through in detail various factors that affect product choice, type of solution, investment objective, and other requirements at an early stage of the project.

A start-up meeting is important to find out about various factors that will affect choice of equipment and solution in order to achieve the most efficient and sustainable solution. We are happy to set up the start-up meeting as a web meeting or a site visit, depending on your preference. All details and information from the start-up meeting we will summarise and go through with you to make sure we agree on project scope and objective.

Next step, we present a proposed solution, focusing on function, lifespan, quality, choice of material, operating and maintenance costs, and environmental impact. Our goal is to deliver a sustainable solution that creates added value to your company,